Lelee anyị ka ọ na-eme!

Ihe Nlereanya ama ama na-eso

TIG welding Ike isi iyi, akwụkwọ ntuziaka&Robot nlereanya, Kwado usoro nkwukọrịta dị iche iche

WSME 315/400/500/630

Igwe ịgbado ọkụ AC na DC pulse argon arc

Ọrụ:

AC TIG dị ugbu a, AC pulse TIG, DC TIG na-adị ugbu a, AC pulse TIG, ịgbado ọkụ nke uche-arc.

Ụlọ ọrụ ngwa:

Aerospace, ohere nkewa, petrochemical ụlọ ọrụ, okpomọkụ Exchanger, aluminum arịa ụlọ na igwe igwe ọkụ.

Atụmatụ:

Ogwe ọrụ na nhazi ezi uche dị na ya, ọrụ bara ụba na ọrụ dị mma;

◆The ịgbado ọkụ oke nwere ike preset kpomkwem;

◆The AC ugboro na obosara ihicha nwere ike gbanwee onwe ya iji gboo mkpa nke ịgbado ọkụ usoro maka dị iche iche aluminum ngwaahịa;

◆Ọ nwere mgbatị arc dị mfe, arc eletrik kwụsiri ike na ọdọ mmiri weld na-achịkwa ngwa ngwa;

◆Mgbado ọkụ argon arc nwere ike ichebe egbe ịgbado ọkụ site na mmebi mmiri;

◆The ịgbado ọkụ ugbu a nwere ike ịchịkwa anya;

◆The weld penetration na weld obosara chọrọ site weld nkwonkwo na ọnụ ọgụgụ nke waveform nwere ike nweta site ukpụhọde nke usu ugbu a, mkpali ugboro, ọrụ ruru, alternating ugbu a, AC ugboro, ihicha nkezi na AC bias ratio mgbe AC argon. A na-eji ịgbado ọkụ arc iji mee ka ndụ ọrụ dị ogologo, nke dabara adaba maka ịgbado ọkụ akpaka na ịgbado ọkụ robot.

| Nlereanya | WSME- -315R | WSME-400 | WSME-500 | WSME-630 |

| Ntinye voltaji/ugboro ugboro | Nkeji atọ 380V(+/-) 10% 50Hz | |||

| Ike ntinye akwadoro (KVA) | 12.1 | 17.1 | 25.7 | 34.7 |

| Ntinye aka ugbu a (A) | 18.5 | 26 | 39 | 53 |

| Ogo nkwado ibu (%) | 60 | 60 | 60 | 60 |

| Mpụta voltaji anaghị ebu ibu (V) | 63 | 70 | 79 | 79 |

| Nsonaazụ dị ugbu a (A) | 5-315 | 5-400 | 20-500 | 20-630 |

| Arc malite ugbu a (A) | 10-315 | 10-400 | 20-500 | 20-630 |

| Ọnụ kacha elu ugbu a (A) | 5-315 | 10-400 | 20-500 | 20-630 |

| Arc na-akwụsị ugbu a (A) | 5-315 | 10-400 | 20-500 | 20-630 |

| Oge mbupu (S) | 0.1-15 | |||

| Oge nkwụsị gas na-adalata (S) | 0.1-20 | |||

| Ugboro ugboro (Hz) | 0,2-20 | |||

| Ọrụ mkpụrụ akụ (%) | 1 ~ 100% | |||

| Ugboro AC (Hz) | 20-200 | 20-200 | 20-100 | 20-100 |

| TIG pilot arc style | HF arc | |||

| Ntụnye ugbu a (A) | 30-315 | 50-400 | 50-500 | 50-630 |

| Ọnọdụ jụrụ oyi | Mmiri jụrụ oyi | |||

| Ọkwa mkpuchi | H/B | |||

WSM 315/400/500

Igwe ịgbado ọkụ DC pulse argon arc tụgharịrị

Ọrụ:

DC na-adị ugbu a TIG, DC usu TIG, akwụkwọ ntuziaka metal-arc ịgbado ọkụ.

Ụlọ ọrụ ngwa:

Ụlọ ọrụ Petrochemical, ụgbọ mmiri nrụgide, ihe owuwu ọkụ eletrik, ụgbọ mmiri, igwe kwụ otu ebe, ike nuklia na ntinye ọkpọkọ.

Atụmatụ:

◆ The ọrụ panel na ezi uche layout, ọgaranya ọrụ na adaba ọrụ;

◆Parameters dị ka ngwa ngwa ịrị elu na ngwa ngwa mgbada eletriki ugbu a, ugboro mkpali, ọrụ ruru, oge nke elu gas ọkọnọ na lagged gas ọkọnọ nwere ike ịtọziri ya kpọmkwem;

◆ The akwụkwọ ntuziaka metal-arc ịgbado ọkụ nwere ike ịgbanwe ọkụ eletrik ugbu a nke arc pụtara na ịkwanye, na-adị mfe ikuta nke arc na igbochi adhesion nke ịgbado ọkụ mkpanaka;

◆Mgbado ọkụ argon arc nwere ike ichebe egbe ịgbado ọkụ site na mmebi mmiri;

◆Ọ nwere abụọ-nzọụkwụ na anọ-nzọụkwụ ịgbado ọkụ ụdịdị;

◆Ọ dị obere ma dị mfe ma dị mma maka mmegharị;

◆A nwere ike igosi ihe dị ugbu a na voltaji n'otu oge.The ịgbado ọkụ ugbu a nwere ike atọrọ kpọmkwem;

◆TIG nwere ike họrọ ụzọ nke elu ugboro elu nke arc pụtara ìhè.

| Nlereanya | WSM-315 | WSM-400 | WSM-500 | ||

| voltaji/ugboro ugboro ntinye akwadoro | Atọ- nkeji 380V(+/-) 10% 50Hz | ||||

| Ike ntinye akwadoro (KVA) | 11.2 | 17.1 | 23.7 | ||

| Ntinye aka ugbu a (A) | 17 | 26 | 36 | ||

| Ogo nkwado ibu (%) | 60 | 60 | 60 | ||

| DC na-agbado ọkụ ugbu a (A) | 5-315 | 5-400 | 5-500 | ||

| DC usu | Ọnụ kacha elu ugbu a (A) | 5-315 | 5-400 | 5-500 | |

| Isi ihe ugbu a (A) | 5-315 | 5-400 | 5-500 | ||

| Ọrụ mkpụrụ akụ (%) | 1 ~ 100 | ||||

| Ugboro ugboro (Hz) | 0,2-20 | ||||

| TIG | Arc malite ugbu a (A) | 10-160 | |||

| Arc na-akwụsị ugbu a (A) | 5-315 | 5-400 | 5-500 | ||

| Oge mbupu (S) | 0.1-15 | ||||

| Oge nkwụsị nke gas - nkwụsị (S) | 0.1-20 | ||||

| TIG pilot arc style | HF arc | ||||

| Aka arc ịgbado ọkụ ugbu a (A) | 30-315 | 40-400 | 50-500 | ||

| Ọnọdụ jụrụ oyi | Mmiri jụrụ / ikuku jụrụ oyi | ||||

| Shell nchedo ọkwa | IP21S | ||||

| Ọkwa mkpuchi | H/B | ||||

WSM-S/YS 400

Igwe ịgbado ọkụ DC pulse argon arc tụgharịrị

| Nlereanya | WSM-400S/YS | ||

| voltaji/ugboro ugboro ntinye akwadoro | Atọ- nkeji 380V(+/-) 10% 50Hz | ||

| Ike ntinye akwadoro (KVA) | 17.1 | ||

| Ntinye aka ugbu a (A) | 26 | ||

| Ogo nkwado ibu (%) | 60 | ||

| DC na-agbado ọkụ ugbu a (A) | 5-400 | ||

| DC usu | Ọnụ kacha elu ugbu a (A) | 5-400 | |

| Isi ihe ugbu a (A) | 5-400 | ||

| Ọrụ mkpụrụ akụ (%) | 1 ~ 100 | ||

| Ugboro ugboro (Hz) | 0,2-20 | ||

| Oge mbupu (S) | 0.1-15 | ||

| Oge nkwụsị nke gas - nkwụsị (S) | 0.1-20 | ||

| Ụdị arụ ọrụ nke arc na-akwụsị ugbu a | Nzọụkwụ abụọ, nzọụkwụ anọ | ||

| TIG pilot arc style | HF arc | ||

| Ọnọdụ jụrụ oyi | Mmiri jụrụ / ikuku jụrụ oyi | ||

| Shell nchedo ọkwa | IP21S | ||

| Ọkwa mkpuchi | H/B | ||

Ọrụ:

DC na-adị ugbu a TIG, DC pulse TIG.

Ụlọ ọrụ ngwa:

Ụlọ ọrụ Petrochemical, ụgbọ mmiri nrụgide, ihe owuwu ọkụ eletrik, ụgbọ mmiri, igwe kwụ otu ebe, ike nuklia na ntinye ọkpọkọ.

Atụmatụ:

◆ The ọrụ panel na ezi uche layout, ọgaranya ọrụ na adaba ọrụ;

◆Parameters dị ka ngwa ngwa ịrị elu na ngwa ngwa mgbada eletriki ugbu a, ugboro mkpali, ọrụ ruru, oge nke elu gas ọkọnọ na lagged gas ọkọnọ nwere ike ịtọziri ya kpọmkwem;

◆ The akwụkwọ ntuziaka metal-arc ịgbado ọkụ nwere ike ịgbanwe ọkụ eletrik ugbu a nke arc pụtara na ịkwanye, na-adị mfe ikuta nke arc na igbochi adhesion nke ịgbado ọkụ mkpanaka;

◆Mgbado ọkụ argon arc nwere ike ichebe egbe ịgbado ọkụ site na mmebi mmiri;

◆Ọ nwere abụọ-nzọụkwụ na anọ-nzọụkwụ ịgbado ọkụ ụdịdị;Ọ dị ntakịrị ma dị ọkụ ma dị mma maka mmegharị;

◆A nwere ike igosi ihe dị ugbu a na voltaji n'otu oge.The ịgbado ọkụ ugbu a nwere ike atọrọ kpọmkwem;

◆TIG nwere ike họrọ ụzọ nke elu ugboro eweli nke arc pụtara ìhè;

◆The wuru na-na ike waya nri usoro nwere ọgaranya ọrụ menus nke waya nri, nke nwere ike izute dị iche iche usoro chọrọ;

◆The waya ndepụta ọnụego na usu ugbu a egwuregwu na-akpaghị aka.

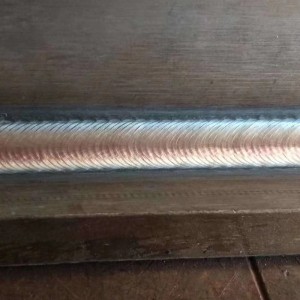

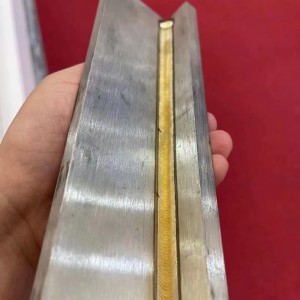

Ntụle nke Welder

Mgbe a na-ejikọta efere ígwè abụọ nwere ọkpụrụkpụ dị iche iche, iji zere nrụgide nrụgide siri ike na-akpata site na mgbanwe ngwa ngwa nke akụkụ obe, a na-ejikarị nwayọọ nwayọọ na-eme ka ọnụ ọnụ efere ahụ dị arọ iji nweta otu nha ahụ n'akụkụ abụọ ahụ.Ike static na ike ọgwụgwụ nke nkwonkwo butt dị elu karịa nkwonkwo ndị ọzọ.Maka njikọ dị n'okpuru mgbanwe, ibu ujo ma ọ bụ na-arụ ọrụ na obere okpomọkụ na arịa nrụgide dị elu, a na-ahọrọkarị ịgbado nkwonkwo ụkwụ.Nkwadebe tupu ịgbado ọkụ nke nkwonkwo ụkwụ dị mfe, mgbakọ ahụ dị mma, na nrụrụ ịgbado ọkụ na nrụgide fọdụrụnụ dị ntakịrị, n'ihi ya, a na-ejikarị ya eme ihe na ntinye nke nkwonkwo na ihe ndị na-adịghị mkpa na saịtị.N'ozuzu, nkwonkwo ụkwụ adịghị mma maka ịrụ ọrụ n'okpuru ọnọdụ dịka ibu ndị ọzọ, mgbasa ozi na-emebi emebi, elu ma ọ bụ obere okpomọkụ.Ojiji nke nkwonkwo T na nkwonkwo nkuku na-abụkarị n'ihi mkpa nhazi.Njirimara na-arụ ọrụ nke welds fillet na-ezughị ezu na nkwonkwo T yiri nkedo fillet na nkwonkwo ụkwụ.Mgbe weld bụ perpendicular na ntụziaka nke mpụga ike, ọ na-aghọ a n'ihu fillet weld.N'oge a, ọdịdị nke weld elu ga-eme ka ọkwa dị iche iche nke nrụgide nrụgide;nrụgide nke penetration fillet weld yiri nke nkwonkwo butt.

Gịnị mere Họrọ anyị

ANYỊ bụ ihe okike

BINGOna-eme nchọpụta na-aga n'ihu ma na-etoliteteknụzụ ịgbado ọkụ nwere ọgụgụ isika ọzọ ịgbado ọkụ akụrụngwagaba uwa

ANYỊ na-anụ ọkụ n'obi

Ugbu a emetụtala ma kwado yasite n'ọtụtụ mban'ọdịnihu

ANYỊ dị egwu

Anyị ga-etinyekwu ego na yana-aga n'ihu r & d na mmepụtagaba n'ihuakwụsịkwala