Robot ịgbado ọkụ TIG

Okwu Mmalite ngwaahịa

A na-ejikarị GTAW na-agbakọta akụkụ ndị dị mkpa nke igwe anaghị agba nchara na ọla ndị na-abụghị ígwè dị ka aluminom, magnesium na ọla kọpa. Usoro a na-enye onye na-arụ ọrụ ikike ịchịkwa weld karịa usoro ịsọ mpi dị ka ịgbado ọkụ igwe mkpuchi mkpuchi na ịgbado ọkụ ígwè gas, na-enye ohere maka ịgbado ọkụ siri ike ma dị elu. Agbanyeghị, GTAW na-atụnyere mgbagwoju anya ma sie ike ịmụta, yana ọzọ, ọ na-eji nwayọ nwayọ karịa ọtụtụ usoro ịgbado ọkụ ndị ọzọ. Usoro metụtara ya, plasma arc welding, na-eji ọwa ịgbado ọkụ dịtụ iche iji mepụta arc ịgbado ọkụ na-elekwasị anya karị, n'ihi ya, a na-akpachapụ anya.

Yunhua na-eji usoro mgbochi pụrụ iche n'oge ịgbado ọkụ TIG, a ga-enwekwa akwụkwọ ntuziaka pụrụ iche maka onye ọrụ, naanị ma ọ bụrụ na onye ọrụ nwere ike ịgbaso ntuziaka ahụ ma na-eme ọtụtụ oge, enwere ike mụta ya ngwa ngwa.

PARAMETER & nkọwapụta ngwaahịa

| Nlereanya | WSM-315R | WSM-400R | WSM-500R | |

| Ntinye voltaji/ ugboro ugboro | Nkeji atọ 380V (+/-) 10% 50Hz | |||

| Ike ntinye akwadoro (KVA) | 11.2 | 17.1 | 23.7 | |

| Ntinye aka ugbu a (A) | 17 | 26 | 36 | |

| Ogo nkwado ibu (%) | 60 | 60 | 60 | |

| DC na mgbe niile ugbu a | Welding curren (A) | 5-315 | 5-400 | 5-500 |

| DC usu | Ọnụ kacha elu ugbu a (A) | 5-315 | 5-400 | 5-500 |

| Base current (A) | 5-315 | 5-400 | 5-500 | |

| Ọrụ Pulse (%) | 1 ~ 100 | 1 ~ 100 | 1 ~ 100 | |

| Ugboro usu (Hz) | 0,2-20 | |||

| TIG | Arc malite ugbu a (A) | 10-160 | 10-160 | 10-160 |

| Arc stop current (A) | 5-315 | 5-400 | 5-500 | |

| Oge nke ugbu a-na-abawanye (S) | 0.1-10 | |||

| Oge nke ugbu a-ebelata (S) | 0.1-15 | |||

| Oge mbupu (S) | 0.1-15 | |||

| Oge nkwụsị nke nkwụsị gas (S) | 0.1-20 | |||

| Ụdị arụ ọrụ nke arc na-akwụsị ugbu a | Nzọụkwụ abụọ, nzọụkwụ anọ | |||

| TIG pilot arc style | HF arc | |||

| Aka arc ịgbado ọkụ ugbu a | 30-315 | 40-400 | 50-500 | |

| Ọnọdụ jụrụ oyi | Mmiri jụrụ oyi | |||

| Ọkwa nchekwa shell | 1P2S | |||

| Ọkwa mkpuchi | H/B | |||

Ngwa

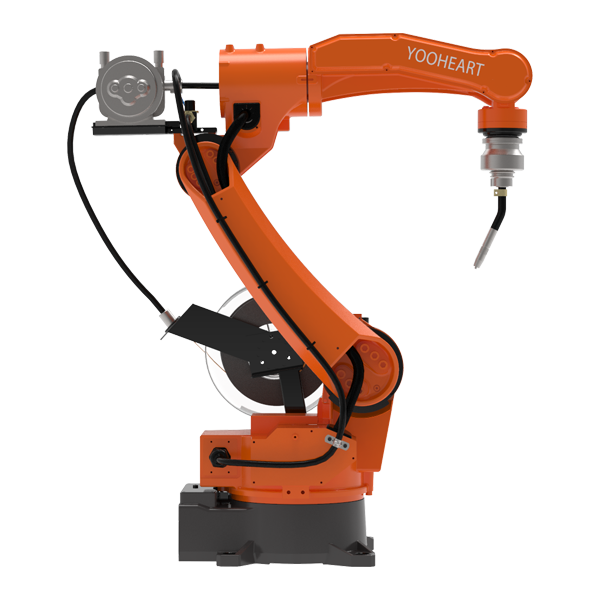

Foto 1

Okwu mmalite

Robot ịgbado ọkụ maka igwe eletrik

Pulse Tig ịgbado ọkụ usoro maka azụ ọnụ ọgụgụ weld onuete.

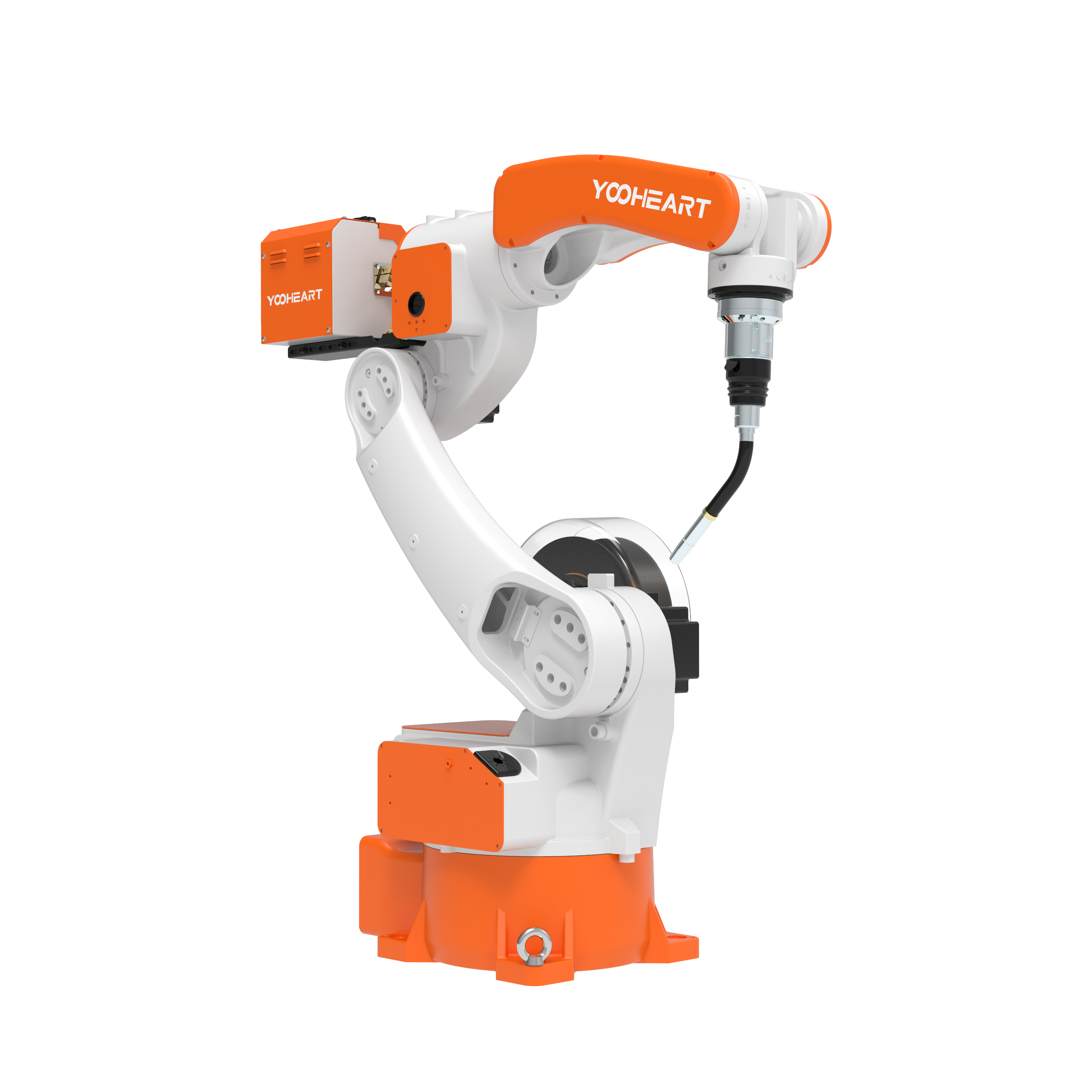

Foto nke 2

Okwu mmalite

Tig welding robot maka igwe anaghị agba nchara

Tig arc ịgbado ọkụ maka square ọkpọkọ ịgbado ọkụ.

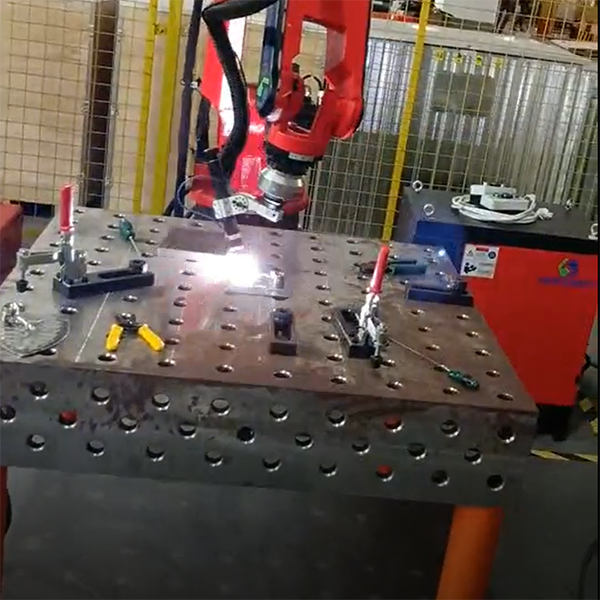

Foto nke 3

Okwu mmalite

Oke nke TIG welder welder

Pulse Tig ịgbado ọkụ arụmọrụ. Ọkpụrụkpụ: 1.5mm, njehie dabara adaba: ± 0.2mm.

Mbupu na Mbupu

Yunhua nwere ike ịnye ndị ahịa usoro nnyefe dị iche iche. Ndị ahịa nwere ike ịhọrọ ụzọ mbupu site n'oké osimiri ma ọ bụ ikuku dị ka mkpa ngwa ngwa siri dị. YOO HEART robot igbe nwere ike izute ihe achọrọ n'oké osimiri na ikuku. Anyị ga-akwado faịlụ niile dị ka PL, asambodo mmalite, akwụkwọ ọnụahịa na faịlụ ndị ọzọ. Enwere onye ọrụ nke isi ọrụ ya bụ ijide n'aka na enwere ike ibuga robot ọ bụla n'ọdụ ụgbọ mmiri ndị ahịa n'enweghị nsogbu n'ime ụbọchị ọrụ 40.

Mgbe ọrụ ire ere

Onye ahịa ọ bụla kwesịrị ịma ROO HEART robot nke ọma tupu ha azụta ya. Ozugbo ndị ahịa nwere otu ROO HEART robot, onye ọrụ ha ga-enwe ọzụzụ ụbọchị 3-5 n'efu na ụlọ ọrụ YOO HEART. A ga-enwe otu Wechat ma ọ bụ WhatsApp Group, ndị ọrụ nka anyị na-ahụ maka ọrụ ire ere, eletriki, ngwa ngwa, sọftụwia, wdg, ga-abanye n'ime ya, ọ bụrụ na otu nsogbu emee ugboro abụọ, onye na-ahụ maka ọrụ anyị ga-agakwuru ụlọ ọrụ ndị ahịa iji dozie nsogbu ahụ.

FQA

Q1. Kedu ngwa kacha mma maka sistemụ ịgbado ọkụ TIG robot?

A.High-olu, ngwa dị iche iche dị iche iche dabara nke ọma maka ịgbado ọkụ nke robot; Otú ọ dị, obere olu, ngwa dị iche iche dị elu nwekwara ike ịrụ ọrụ ma ọ bụrụ na ejiri ngwá ọrụ kwesịrị ekwesị tinye ya. Ndị ụlọ ọrụ ga-achọ ịtụle ego agbakwunyere maka iji ngwá ọrụ iji chọpụta ma ọ bụrụ na usoro ịgbado ọkụ nke rọbọt ka nwere ike inye nloghachi siri ike na ntinye ego mbụ. Banyere ịgbado ọkụ TIG, ngwa kachasị mma bụ iberibe na ọla.

Q2. Kedu nke na-eji mma? HF TIG ịgbado ọkụ ma ọ bụ ebuli TIG ịgbado ọkụ?

A. Nhọrọ kachasị ewu ewu na nke kachasị mma bụ iji High Frequency mmalite nke na-emepụta arc ugboro dị elu nke nwere ike ime ka ikuku ionizing na ikpokọta ọdịiche dị n'etiti ebe tungsten na mpempe ọrụ. Mmalite Frequency dị elu bụ usoro na-adịghị emetụ aka ma na-emepụta ihe fọrọ nke nta ka ọ bụrụ mmetọ ọ gwụla ma tungsten agbachaala nkọ ma ọ bụ amperage na-atụgharị elu na mmalite. Ọ bụ nhọrọ magburu onwe ya maka ịgbado ọkụ aluminom, ma n'ezie bụ naanị nhọrọ a na-anabata. Ọ gwụla ma ịchọrọ ịgbanye Aluminom, ịgaghị enwe mmalite mmalite Frequency dị elu, mana ọ dị mma ịgbanye AC ma ọ bụ DC ma ọ bụrụ na ị nwere nhọrọ.

Q3. YOO HEART TIG rọbọt ịgbado ọkụ nwere ike iji filler?

A.Ee, anyị bụ otu n'ime mmadụ ole na ole nwere ike iji filler mgbe TIG ịgbado ọkụ. Ọtụtụ ndị na-ebubata ahịa n'ahịa nwere ike ịgwa gị na enwere ike iji robots ha maka ịgbado ọkụ TIG, ị nwere ike jụọ ya ajụjụ ndị dị ka: otu esi enyocha HF?

Q4. Otu esi edobe isi iyi ike mgbe ị na-eji ịgbado ọkụ TIG?

A.Your welding machine should be to DCEN (Direct current electrode negative) nke a makwaara dị ka polarity kwụ ọtọ maka mpempe ọrụ ọ bụla nke kwesịrị ịgbado ọ gwụla ma ha bụ aluminom ma ọ bụ magnesium. Edebere ugboro dị elu ka ịmalite nke a na-ahụ n'oge a n'ime inverters. Ekwesịrị ịtọ eruba akwụkwọ ozi opekata mpe 10 sekọnd. Ọ bụrụ na A/C dị, a na-edozi ya na ntọala ndabara nke dabara na DCEN. Tọọ kọntaktị na amperage switches na ntọala dịpụrụ adịpụ. Ọ bụrụ na ihe a chọrọ ka welded bụ aluminom polarity kwesịrị ịtọ ka A / C, A / C itule kwesịrị ka 7 na elu ugboro ọkọnọ kwesịrị na-aga n'ihu.

Q5. Kedu ka esi edobe ọta gas n'oge ịgbado ọkụ TIG?

A. TIG ịgbado ọkụ na-eji gas inert maka kpuchido ebe ịgbado ọkụ site na mmetọ. Ya mere, a na-ekwukwa gas inert dị ka gas na-echebe. N'ọnọdụ ọ bụla, ọ ga-abụ argon na enweghị gas ọzọ inert dị ka neon ma ọ bụ xenon wdg karịsịa ma ọ bụrụ na a ga-eme ịgbado ọkụ TIG. Ekwesịrị ịtọ ya ihe dịka 15 cfh. Maka ịgbado ọkụ aluminom naanị ị nwere ike iji ngwakọta 50/50 nke argon na helium.