Ụlọ ọrụ ụgbọ ala bụ ihe ọhụrụ, na-achọ izi ezi, ọsọ na ntụkwasị obi n'ichepụta akụrụngwa. N'ime akụkụ ụgbọ ala dị oke egwu, sistemu iyuzucha—karịsịa ọkpọkọ ọkpọkọ — na-arụ ọrụ dị mkpa n'ịrụ ọrụ ụgbọ ala, njikwa ikuku, na mbelata mkpọtụ. Dị ka ndị na-emepụta ihe na-agbalịsi ike izute ụkpụrụ dị mma na ebumnuche mmepụta, robots ịgbado ọkụ apụtala dị ka ngwá ọrụ dị mkpa n'ichepụta sistemu ikuku. Edemede a na-enyocha ka sistemu ịgbado ọkụ nke rọbọt, jikọtara ya na ngwa nrụnye dị elu dịkarotary tilt positionersnaihe ndozi ahaziri ahazi, na-agbanwegharị mmepụta nke ọkpọkọ ikuku akpaaka, na-ebuli arụmọrụ, nkwụsi ike, na àgwà ngwaahịa ruo ọkwa a na-enwetụbeghị ụdị ya.

1. Mgbagwoju anya nke nrụpụta ọkpọkọ mkpofu

A na-edobe ọkpọkọ ikpochapụ n'ọnọdụ dị oke egwu, gụnyere oke okpomọkụ, ikuku na-emebi emebi, na ịma jijiji n'ibu. Iji nagide ihe ịma aka ndị a, a na-esi na igwe anaghị agba nchara ma ọ bụ alumini mee ha ma na-achọkwa welds na-adịghị mma, ikuku na-agafe n'ofe geometric dị mgbagwoju anya. Usoro ịgbado ọkụ akwụkwọ ntuziaka ọdịnala na-agbakarị mgba iji nọgide na-agbanwe agbanwe na ngwa ndị dị otú ahụ, na-ebute ntụpọ dị ka porosity, ngwakọta ezughị ezu, ma ọ bụ mgbagha.

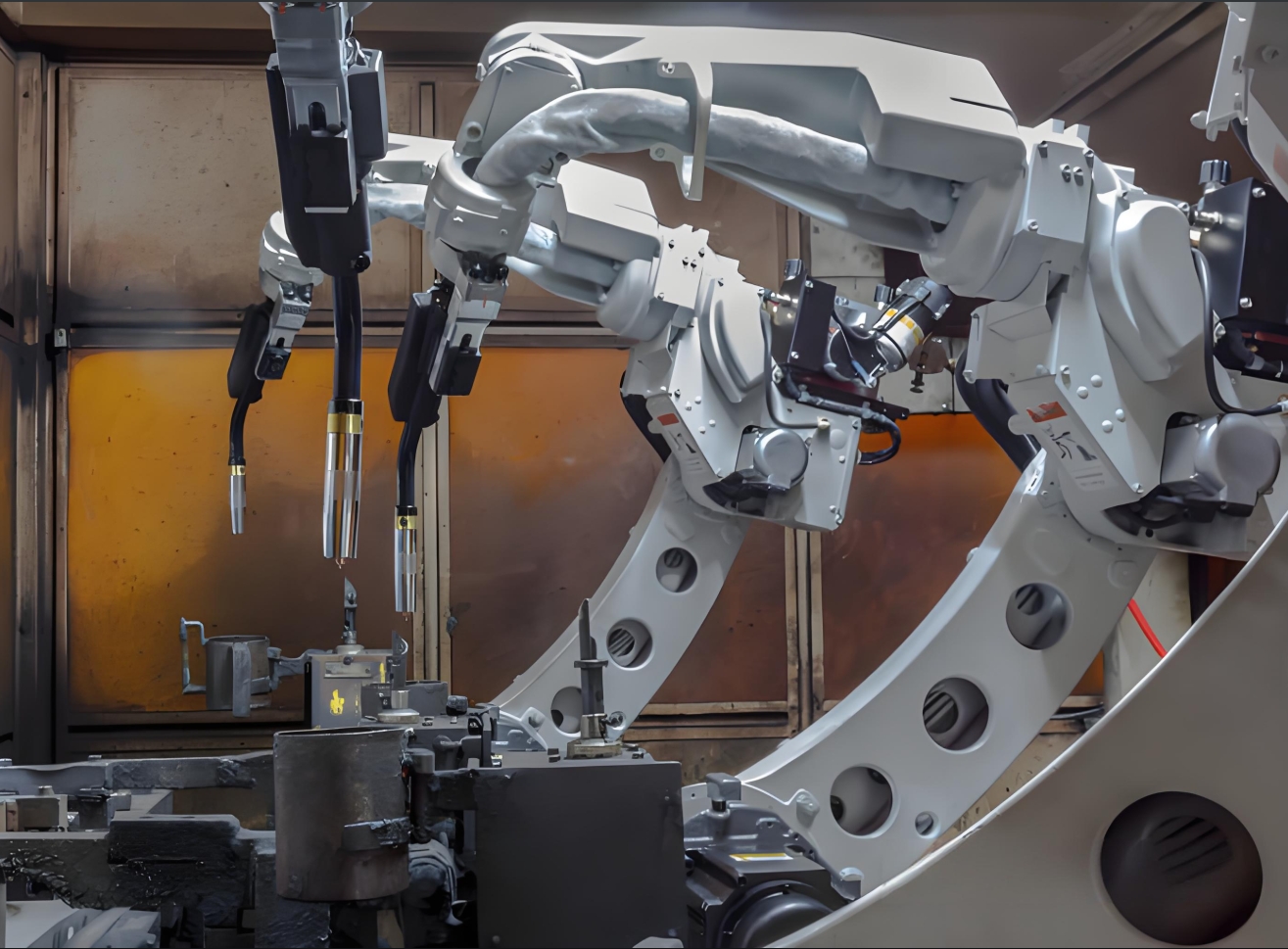

Otú ọ dị, ígwè ọrụ ịgbado ọkụ na-eme nke ọma n'ijikwa ihe mgbagwoju anya ndị a. N'ịbụ ndị ejiri nhịahụ multi-axis na-arụkọ ọrụ na usoro nhazi nkenke, ha na-ebuga welds na-enweghị ntụpọ n'elu ala gbagọrọ agbagọ, flanges, na nkwonkwo-dị oke mkpa maka ịgba mbọ hụ na sistemu iyuzucha zuru oke.

2. Robotic Welding in Action: Key Applications for Exhaust Pipes

2.1 Tube-to-Flange na Tube-to-Muffler Welding

Sistemụ mkpochapụ nwere ọtụtụ ihe, gụnyere ọkpọkọ, ndị na-atụgharị catalytic, resonators, na mufflers. Sistemụ ịgbado ọkụ robotic na-eme ka njikọ nke ọkpọkọ gaa na flanges ma ọ bụ ụlọ muffler, na-eme ka ntinye n'otu na-ebelata mpaghara okpomọkụ metụtara (HAZ). Dịka ọmụmaatụ, a6-axis articulated robotnwere ike imegharị gburugburu ọkpọkọ, na-ejigide akụkụ ọwa na ọsọ ọsọ ọbụna n'elu ebe a na-adọkpụ.

2.2 Welding laser maka akụrụngwa nwere mgbidi

Ọkpụkpọ ikuku nke oge a na-egosipụtakarị atụmatụ nwere mgbidi dị mkpa iji belata ibu ma na-ejigide ike. Robots ịgbado ọkụ laser, nwere ike ha dị elu yana eriri weld dị warara, na-egbochi ọgụ ma chekwaa ihe onwunwe. Nke a bara uru karịsịa maka sistemu igwe anaghị agba nchara, ebe nkenke dị oke mkpa.

2.3 Multi-Pass ịgbado ọkụ maka nnukwu nkwonkwo

Maka sistemu ikpochapu ọrụ dị arọ n'ime ụgbọ ala azụmahịa, sistemu robotic gas metal arc welding (GMAW) na-eme welds dị iche iche iji wulite nkwonkwo siri ike n'etiti ọkpọkọ nwere mgbidi na braket. Algọridim na-agbanwe agbanwe na-agbanwe paramita ozugbo iji nabata ọdịiche ihe onwunwe.

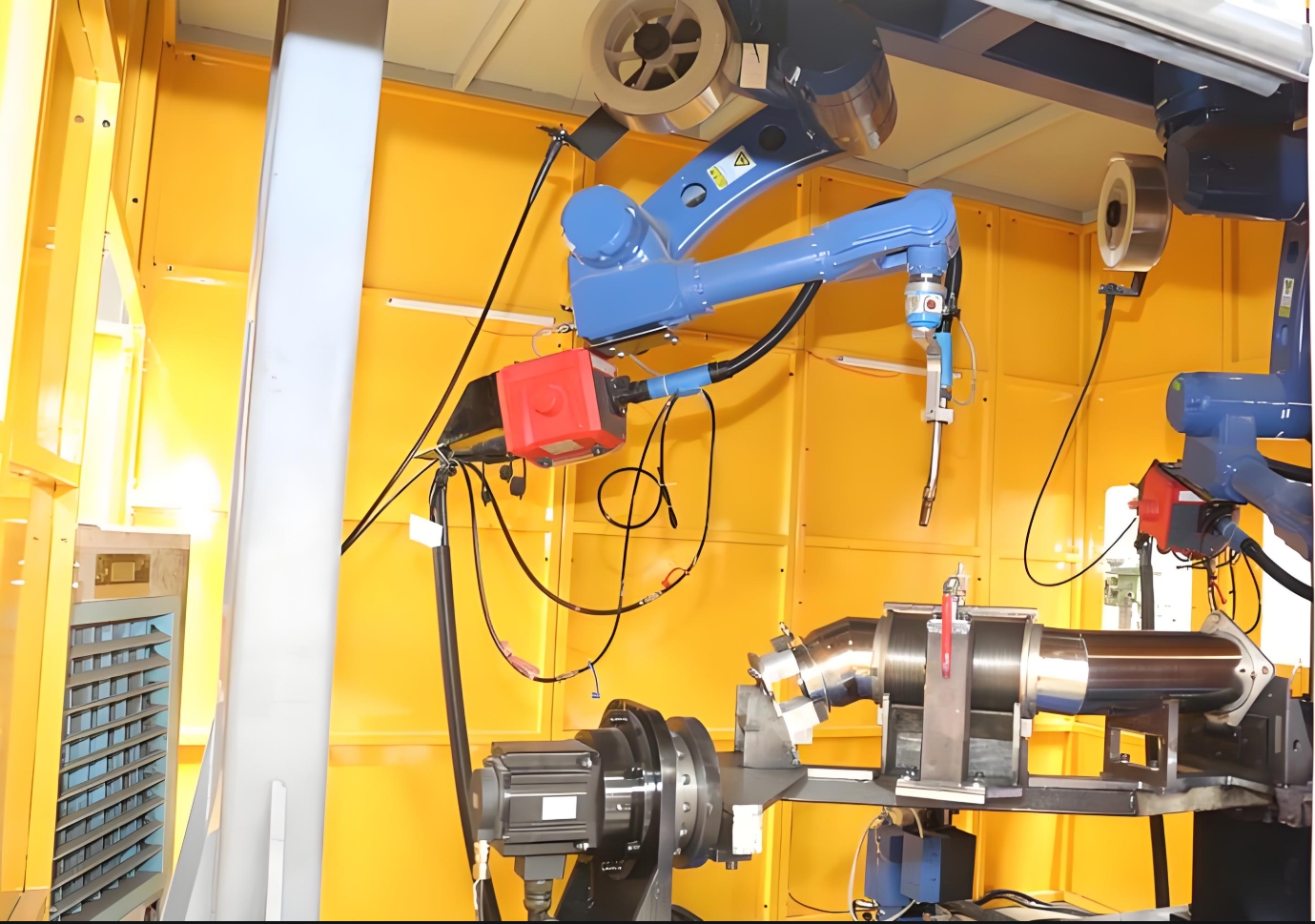

3. Ịkwalite mgbanwe na Rotary Tilt Positioners

Igwe ịgbado ọkụ nke rọbọt na-adabere na nchikota enweghị nkebi n'etiti robot na workpiece.Rotary tilt positionersbụ ihe dị mkpa na usoro a, na-enye ohere ntụgharị ogo 360 na ịgbatị ọkpọkọ ikuku n'oge ịgbado ọkụ. Uru gụnyere:

- Nnweta nkwonkwo kacha mma: The positioner reorients ọkpọkọ na-ewetara weld onuete na larịị ma ọ bụ kehoraizin ọnọdụ, mfe robot mmemme na mbenata okirikiri ugboro.

- Mbelata ndogharị: Site n'ịgbanwe ihe na-arụ ọrụ nke ọma, robot nwere ike mezue ọtụtụ weld n'otu nhazi, na-ebelata oge efu.

- Ergonomics emelitere: Ndị na-arụ ọrụ na-ebu / na-ebupụ ihe ndị na-emepụta ihe mgbe robot na-agbakọ, na-eme ka ọ dịkwuo mma.

Dịka ọmụmaatụ, ebe ọdụ ụgbọ ala abụọ na-enye ohere ịgbado otu ọkpọkọ ebe a na-ebu nke ọzọ, na-arụpụta mmepụta ihe na-aga n'ihu.

4. Ndozi nkenke: Ọkpụkpụ azụ nke ịdị n'otu

ahaziriihe mgbado ọkụdị oke mkpa maka ijide ihe ndị mejupụtara iyuzucha n'otu oge n'oge ịgbado ọkụ nke rọbọt. Isi ihe nleba anya imewe gụnyere:

- Usoro njigide: Mkpọchi pneumatic ma ọ bụ hydraulic echekwabara ọkpọkọ, flanges na braket na-enweghị ebe ọ bụla.

- Modulity: Ngwa ngwa-mgbanwe ngwa ngwa na-anabata ndị dị iche iche ọkpọkọ dayameta ma ọ bụ nhazi, dị mma maka mmepụta ihe nlereanya.

- Njikwa okpomọkụ: Ihe ndozi sitere na ihe na-eguzogide okpomọkụ na-eguzogide ogologo oge na arcs ịgbado ọkụ.

Ihe nrụnye dị elu na-ejikọta sensọ iji nyochaa ntinye akụrụngwa tupu ịgbado ọkụ amalite, na-ewepụ ntụpọ adịghị mma.

5. Ịkọwapụta uru bara uru

Nkwenye nke sistemu ịgbado ọkụ nke rọbọt n'ichepụta ọkpọkọ anwụrụ ọkụ na-eweta nkwalite ndị nwere ike ịtụte:

- Mbelata Oge okirikiri: A Robot MIG welder nwere ike mechaa eriri okirikiri n'ime sekọnd 60, ma e jiri ya tụnyere 180+ sekọnd maka ịgbado ọkụ n'aka.

- Oge kacha elu: Robots na-arụ ọrụ 24/7 na obere oge nkwụsị, na-akwalite mmepụta kwa afọ site na 30-50%.

- Nchekwa ihe: Njikwa paramita ziri ezi na-ebelata spatter na rework, na-ebelata ọnụ ahịa oriri site na 15-20%.

Dịka ọmụmaatụ, onye na-ebu ụgbọ ala Tier-1 kọrọ a40% na-abawanye na ntinyemgbe etinyechara sel rọbọt ya na ndị na-arụkọ ọrụ ọnụ maka mgbakọ iyuzucha.

6. Na-ebuli ogo na ụkpụrụ ụgbọ ala

Mgbado ọkụ nke robotic na-eme ka nrube isi na akara ngosi ụgbọ ala dị ka IATF 16949:

- Nkwagharị ugboro ugboro: Robots na-emegharị ụzọ weld na ± 0.1 mm ziri ezi, na-ewepụ mgbanwe mmadụ.

- Nchọpụta ntụpọ: Sistemụ ọhụụ jikọtara ọnụ ma ọ bụ ihe mmetụta arc na-achọpụta ihe adịghị mma n'etiti usoro, na-ebute mmezi ozugbo.

- Akwụkwọ: Sistemu akpaaka na-emepụta ndekọ weld traceable, dị oke mkpa maka nyocha na ncheta.

Nnyocha e mere mgbe weld na-ekpughe na sistemu roboti na-ebelata ogo porosity na mgbawa site na ihe karịrị 90% ma e jiri ya tụnyere usoro ntuziaka.

7. Ịdịgide na Ọdịnihu Ọdịnihu

Ndị na-emepụta ụgbọala na-ebuwanye ibu na-ebute nkwado. Mgbado ọkụ robotic na-akwado mgbanwe a site na:

- Mbelata oriri ike: Oge arc nke ọma yana ụzọ ngagharị kachasị na-ebelata ojiji ike.

- Na-ebelata ihe mkpofu: Ọnụ ọgụgụ mkpụrụ nke ngafe mbụ dị elu na-ebelata nsị.

- Na-eme ka Lightweighting: Ịgbado ọkụ nke ọma na-eme ka iji ihe ndị dị elu dị elu, nke dị gịrịgịrị na-eme ka ọ ghara ịdịte aka.

Na-ele anya n'ihu,Robot ịgbado ọkụ AI na-anyaga-leverage igwe mmụta iji onwe-ebuli parameters maka ọhụrụ ihe, mgberobots na-emekọ ihe ọnụ (cobots)ga-enyere ndị na-arụ ọrụ aka na mmepụta obere obere.

Mmechi

N'ebe dị elu nke nrụpụta sistemu ikuku ụgbọ ala, igwe ịgbado ọkụ - nke ndị nwere ọgụgụ isi na-etinye na ihe ndozi gbagoro - na-anọchi anya ọnụ ọgụgụ kacha elu nke injinia ziri ezi. Site na ịrụ ọrụ ịgbado ọkụ dị mgbagwoju anya, sistemu ndị a na-enye ndị nrụpụta ike ka ha nweta oge okirikiri ngwa ngwa, ịdị mma na-enweghị atụ, yana mmepụta nwere ike ịgbatị. Ka ụkpụrụ mkpochapụ ikuku na-esiwanye ike ma na-emepụta ụgbọ ala na-apụta, teknụzụ ịgbado ọkụ nke rọbọt ga-anọgide na-abụ isi nkuku nke ihe ọhụrụ, na-ebuga ụlọ ọrụ ụgbọ ala na-aga n'ihu mara mma na nke dị ọcha.

Maka ndị na-emepụta roboti ụlọ ọrụ, na-emesi ike ndị a ike na ngwa ikpochapụ ọkpọkọ ọ bụghị naanị na-egosipụta nka nka kamakwa na-edobe ngwọta ha dị ka ndị mmekọ dị mkpa n'ịkwalite ọmarịcha n'ichepụta ụgbọ ala.

Oge nzipu: Mar-21-2025