Site na mmepe nke teknụzụ robot ịgbado ọkụ, ọtụtụ ụlọ ọrụ malitere ịnụ ụtọ oke ịgbado ọkụ nwere ọgụgụ isi, n'ihi na ọ na-enye teknụzụ dị ọnụ ahịa maka ụlọ ọrụ iji nweta ọgụgụ isi, ozi, na akpaaka nke ngwaahịa ịgbado ọkụ. N'ime ụlọ ọrụ dị arọ, ebe a na-arụ ọrụ ịgbado ọkụ robot, nke na-ejikọta teknụzụ robot, usoro ịgbado ọkụ, imewe ihe, teknụzụ na-ahụ maka teknụzụ, teknụzụ njikwa akpaka, yana sistemụ MES na ọzụzụ ndị ọzọ, na-edozi mkpa akụrụngwa akpaaka nke usoro ịgbado ọkụ na nrụpụta maka ụlọ ọrụ. N'ezie, n'agbanyeghị nke ụlọ ọrụ iji nweta ọgụgụ isi ịgbado ọkụ, ọ bụ n'ozuzu kewapụrụ na elu-edu ịgbado ọkụ waya, n'ihi na àgwà nke waya, ga-enwe mmetụta dị ukwuu na nkwụsi ike nke waya nri na ịgbado ọkụ usoro, ịgbado ọkụ àgwà, wdg.

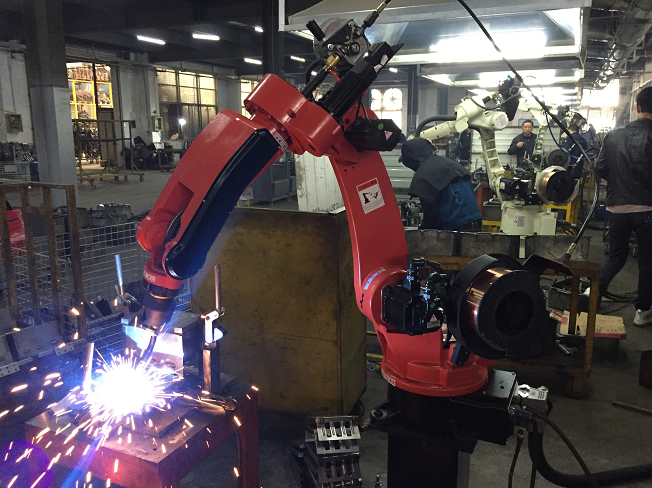

Ihe mejupụtara 1 arc ịgbado ọkụ

Robot arụ ọrụ nwere ike ịme mmemme, anthropomorphic, zuru ụwa ọnụ, na ọgụgụ isi, ma ejirila ya mee ihe n'ọtụtụ ụlọ ọrụ. Enwere ike ijikọ robots ụlọ ọrụ na akụrụngwa ndị ọzọ iji mepụta ntụzịaka ngwa ngwa robot dị iche iche, ngwa a na-ahụkarị gụnyere ịgbado ọkụ, eserese, mgbakọ, mkpokọta na ntinye (dịka nkwakọ ngwaahịa, palletizing, na SMT), nyocha ngwaahịa na nnwale, wdg.

Arc ịgbado ọkụ bụ tumadi ihe mejupụtara arc ịgbado ọkụ ngwa na a robot sistem. The robot usoro na-emi esịnede a robot ahu na njikwa kabinet (ngwaike na arc ịgbado ọkụ software, wdg) .The arc ịgbado ọkụ akụrụngwa na-emi esịnede a ịgbado ọkụ ọkụ, waya nri usoro, ịgbado ọkụ egbe na akụkụ ndị ọzọ. Robots nwere ọgụgụ isi na-ejikwa laser ma ọ bụ ihe mmetụta ọhụụ yana sistemụ njikwa ọkụ eletrik. A na-egosi ebe a na-arụ ọrụ robot ịgbado ọkụ na eserese 1.

Ngwa a na-ahụkarị nke ebe a na-arụ ọrụ igwe ịgbado ọkụ abụọ arc

(1) Ebe a na-arụ ọrụ ịgbado ọkụ nke robot dị mfe Ụzọ kachasị mfe nke arc welding robot workstation bụ otu robot, otu ike ịgbado ọkụ, egbe ịgbado ọkụ na ngwa ngwa. Nke a na ụdị robot ịgbado ọkụ worktation bụ kasị isi, ma ndị ọzọ mgbagwoju robot ịgbado ọkụ akara components. Ọgụgụ 2 na-egosi ebe a na-arụ ọrụ robot ịgbado ọkụ dị mfe. Robot nke ebe a na-arụ ọrụ bụ Fanuc robot, nke bụ onye na-arụ ọrụ nke sistemu arụ ọrụ niile. Ụlọ njikwa njikwa bụ etiti ụbụrụ nke sistemụ robot, nke na-ahụ maka data na nnyefe mgbaàmà nke onye na-eme ihe ma na-achịkwa mmegharị nke onye na-eme ihe. Ngwa nkuzi bụ ihe ntanetị mmadụ-kọmputa, nke onye debugger nwere ike dezie mmemme dịka ihe achọrọ nke ngwaahịa ahụ. The ịgbado ọkụ ike ọkọnọ adopts a Lincoln welder, na robot nwere ike na-ekwurịta okwu na Arclink netwọk, nke bụ adaba maka ịgbado ọkụ mgbama nnyefe n'etiti robot na welder.TBI ịgbado ọkụ egbe na ịgbado ọkụ igwe, ịgbado ọkụ waya na tooling mejupụtara a zuru ezu ụzọ nweta workpiece ịgbado ọkụ.

Site na-ewu nke robot ịgbado ọkụ workstations, ụfọdụ mfe ulo oru ngwaahịa nwere ike na-aghọta akpaka ịgbado ọkụ.As ogologo dị ka ọnọdụ nke ngwaahịa na tooling bụ nke ọma-positioned maka a ụfọdụ ngwaahịa, na online ịgbado ọkụ onuete trajectory ozizi omume na-rụrụ, na usoro parameters nke siri ike ngwaahịa bụ ntinye, na robot nwere ike malite ịghọta na akpaka ịgbado ọkụ nke ngwaahịa. Mgbado ọkụ efere dị arọ nke nwere ebe a na-arụ ọrụ ịgbado ọkụ mara mma n'ọdịdị ma dịkwa mma.

Nke a na ụdị robot ịgbado ọkụ worktation bụ karịsịa adabara ụfọdụ obere workpiece ịgbado ọkụ, dị ka ogologo efere, gburugburu efere na ndị ọzọ workpiece, ike mgbanwe, ọzọ ndakọrịta; Otú ọ dị, enwere nsogbu na ụdị ọrụ a: oge ọ bụla ọ dị mkpa ka a na-ebufe ngwaahịa na aka ya, na ngwaahịa ndị ahụ enweghị ike ijide ya na-akpaghị aka, na-eduga na ọdịda nke ọrụ ịgbado ọkụ nke robot dum iji nweta ịgbado ọkụ na-akpaghị aka n'ezie.

ịgbado ọkụ robot ịgbado ọkụ workstation na mgbakwunye na mfe ịgbado ọkụ workstation isi ngwá, nwekwara onwem na mpụga eletriki akara ngwaọrụ, PC ihuenyo mmetụ, jig, laser n'ọnọdu usoro na uzuzu ngwaọrụ na nlekota usoro na na, site na ndị a mmiri iji wuo a ọzọ zuru ezu ịgbado ọkụ arc ịgbado ọkụ robot workstation, Kpọọ ya onye nwere ọgụgụ isi robotic workstation.An nwere ọgụgụ isi ịgbado ọkụ na-arụ ọrụ na-arụ ọrụ na-arụ ọrụ nke bụ isi nke na-arụ ọrụ nke uzuzu uzuzu na usoro nlekota oru. workpiece, na-enweghị ihe ọ bụla pesonel isonye na ukpụhọde nke akụrụngwa, ya bụ, ịghọta n'ezie unmanned ọrụ.

Oge nzipu: Mar-25-2022